High-Performance VBASE Base Oils for Environmentally Acceptable Hydraulic Fluids

Sea-Land Chemical Company |

A Sustainable Journey Towards Efficiency and Reliability

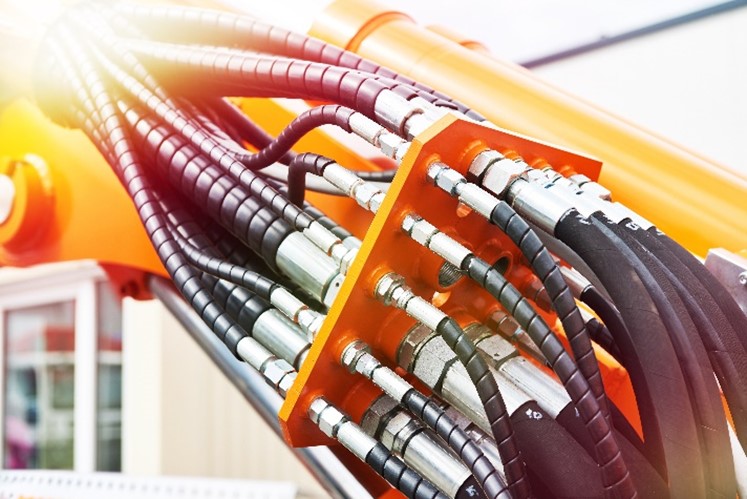

In a world increasingly focused on sustainability, the hydraulic industry is undergoing a profound transformation. Rising system pressures, higher operating temperatures, and the need for more compact designs have driven the demand for hydraulic fluids that are not only efficient and reliable but also environmentally responsible. VBASE® Secondary Polyol Ester™ (SPE™) base oils have emerged as an innovative solution for formulating modern environmentally acceptable hydraulic fluids (HEES), offering outstanding performance across diverse hydraulic systems while aligning with sustainable practices.

A Changing Landscape

Recent trends in the hydraulic industry include the adoption of higher system pressures exceeding 5000 psi, elevated operating temperatures reaching 100°C or higher, and the move towards more compact designs with smaller reservoir sizes. These trends have heightened thermal stresses within systems. VBASE Oil Company recognized these shifts and developed a range of cutting-edge solutions to address these industry challenges.

Performance Needs and VBASE Functionality

Hydraulic systems have specific performance needs, and VBASE SPE™ base oils have been designed to meet these requirements:

- Pump Reliability and Wear Protection: VBASE® base oils have excellent film forming properties due to their oxygen-rich structure, leading to low wear and ensuring the reliable operation of hydraulic pumps.

- Low Compressibility and High Bulk Modulus: VBASE base oils exhibit high bulk modulus values, minimizing compressibility and maintaining system efficiency even under the highest pressures.

- Operating Temperature Range and High Viscosity Index (VI): VBASE® base oils offer higher VI values than traditional hydrocarbon oils and excellent low temperature properties making them versatile for use across all seasons. Because VBASE base oils have higher VI values than conventional saturated esters of similar ISO viscosity grades, this has the potential to result in superior energy efficiency, reducing energy consumption and associated energy costs.

- Deposit and Varnish Control: VBASE base oils’ oxygen-rich structure, a hallmark of VBASE SPE™ technology, helps eliminate the formation of deposits and varnish which are common when using other base oil technologies such as hydrocarbon oils. This improved cleanliness and varnish control enhances equipment reliability, extends the lifespan of critical components, and reduces maintenance expenses.

- Shear Stability: VBASE base oils are shear stable and ensure equipment reliability across a wide range of operating conditions.

- Air Release: VBASE base oils offer faster air release times compared to other synthetics, minimizing the potential for cavitation in equipment and ensuring greater reliability. This is especially important as the industry moves to smaller reservoirs.

- Water Tolerance: VBASE base oils offer excellent hydrolytic stability and good demulsibility when there is water ingress into the fluid. This feature ensures smoother hydraulic system operations. This superior hydrolytic stability leads to longer drain intervals and fewer fluid changes, reducing maintenance costs and operational downtime.

Environmental Acceptability

VBASE Oil Company is committed to offering environmentally friendly base oils without compromising performance. VBASE® Secondary Polyol Ester™ base oils were designed as high-performance alternatives to traditional ester chemistries and are suitable for the most demanding applications in environmentally sensitive areas.

All VBASE® base oils are biobased (inclusion of renewable carbon >50%; certified USDA BioPreferred), readily biodegradable (>80% by OECD 301B), non-toxic (OECD 201, OECD 202, OECD 203, OECD 236), and non-bioaccumulating (OECD 117). VBASE base oils are also certified NSF HX-1 and thus suitable for the formulation of H1 lubricants used in and around food processing areas.

All VBASE base oils are included on the European Ecolabel LuSC-List. Formulators select LuSC-list components for their finished products in order to be considered Environmentally Acceptable Lubricants (EALs) and meet Vessel General Permit (VGP) and Vessel Incidental Discharge Act (VIDA) requirements.

Conclusion

As the hydraulic industry continues to evolve, with heightened demands for performance, efficiency, and environmental responsibility, VBASE® base oils stand as a pioneering solution. With VBASE Secondary Polyol Ester™ base oils’ exceptional performance and environmental friendliness, VBASE customers can formulate unique fluids that will play a role in the future of hydraulics, providing reliability, efficiency, and sustainability to hydraulic systems across various industries.

VBASE BAse OIls For Environmentally Acceptable Hydraulic fluids (HEES)

VBASE 32S, 46S, 46U, and 68U are excellent choices for formulators seeking to create the next generation of modern environmentally acceptable hydraulic fluids (HEES). VBASE 32S and VBASE 46S are especially recommended in formulating fluids where thermal stresses are high such as compact mobile hydraulic systems.

Learn more about novel VBASE® Secondary Polyol Ester™ technology at vbaseoil.com.